A hammer mill is a grinding device utilized to break down or compress materials into smaller fragments. It is widely used in the agricultural, wood, and biomass industries for processing materials such as grains, wood chips, straw, and other biomass feedstocks. In this article, we will discuss the usage, construction, and working principles of a hammer mill.

Construction

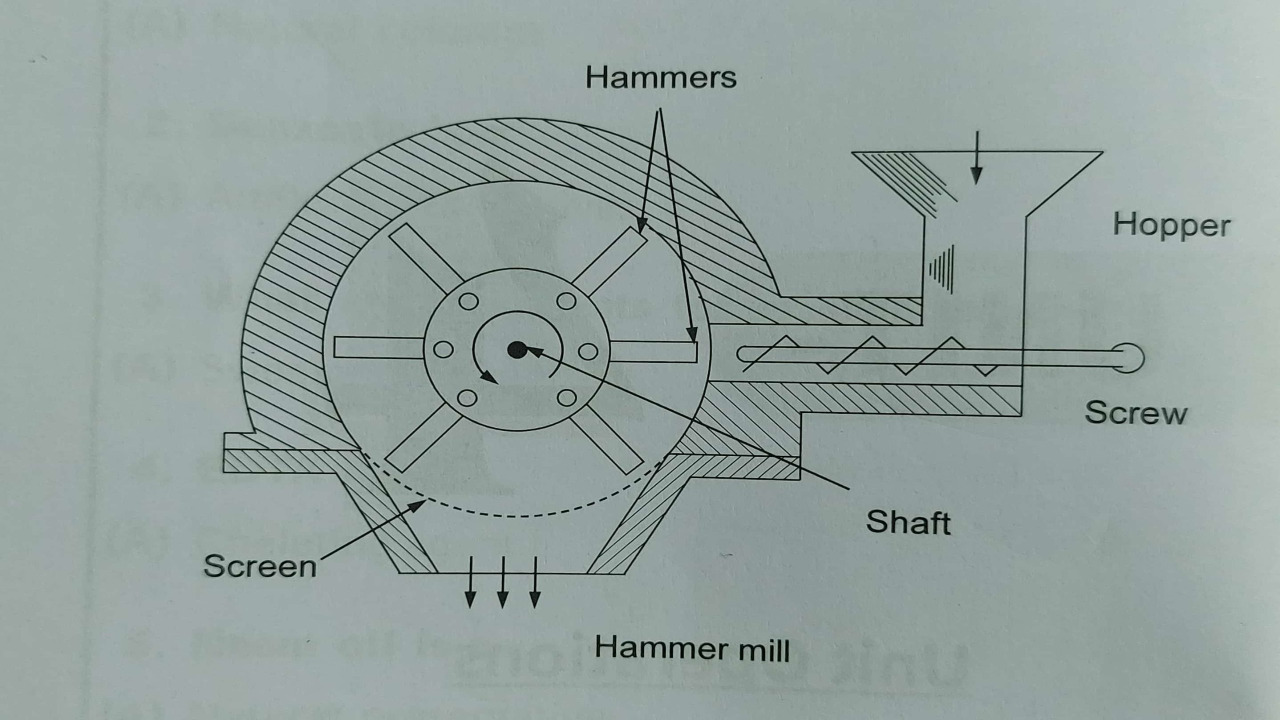

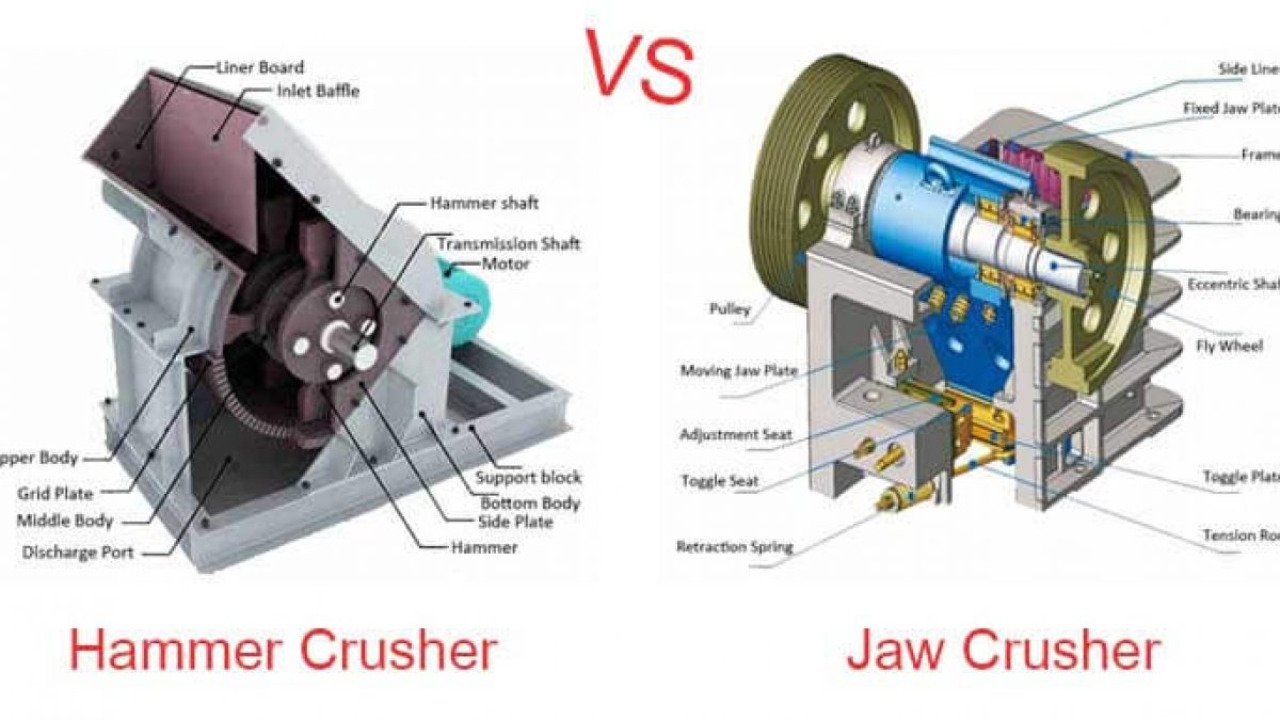

A hammer mill consists of a rotor with a series of hammers attached to it. The rotor spins at high speed, forcing the hammers to swing outward and impact the material being processed. The size and shape of the hammers can vary depending on the application, but they are typically made of steel or another durable material. Read more details here.

The material to be processed is fed into the hammer mill through a hopper or chute. The material is then struck by the hammers and shredded into smaller pieces. The shredded material is then collected in a bag or bin for further processing.

Usage

Hammer mills are commonly used in the following industries:

- Agricultural industry: To grind grains, such as wheat, corn, and barley, for animal feed.

- Wood industry: To process wood chips into small wood particles that can be used to produce wood pellets or other wood-based products.

- Biomass industry: To grind various types of biomass feedstocks, such as straw, corn stover, and switchgrass, into small particles for use in the production of biofuels.

Working Principles

The working principle of a hammer mill is simple. The rotor spins at high speed while the hammers attached to it swing outward, striking the material being processed. The force of the impact causes the material to be shredded into smaller pieces.

The size of the particles produced by a hammer mill depends on the size of the openings in the screen that covers the bottom of the grinding chamber. The screen can be changed to produce particles of different sizes. The finer the screen, the smaller the particles produced.

Hammer mills can be used for both dry and wet grinding. In the case of wet grinding, the material is mixed with water to form a slurry before being fed into the hammer mill. The water helps to lubricate the hammers and reduce the amount of heat generated during the grinding process.

Hammer mills can be powered by electricity, diesel, or gasoline engines. Electric-powered hammer mills are the most common type used for small-scale applications, while diesel-powered hammer mills are more suitable for larger-scale operations where electricity is not readily available.

Conclusion

In conclusion, a hammer mill is a versatile grinding machine used in various industries for processing different types of materials. Its construction is relatively simple, consisting of a rotor with a series of hammers attached to it. The working principle of a hammer mill involves the rotor spinning at high speed, forcing the hammers to swing outward and impact the material being processed. Hammer mills are commonly used in the agricultural, wood, and biomass industries for grinding grains, wood chips, and biomass feedstocks.